BaumaLight TN760

|

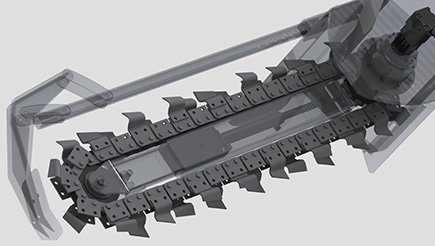

TN760 Trencher for Skidsteer Cut deep trenchers with even more power with the TN760, Baumalight’s most powerful trencher for skidsteers for high flow hydraulics. Save time and money the next time you need to cut a trench to safely bury water lines, gas lines, drainage pipe or electrical lines. Ideal for farmers, landscapers or contractors, Baumalight’s TN760 Trencher will quickly cut trenches an impressive 5 feet deep and between 6” to 10” wide. The TN760 Trencher is powered by a how flow motor for up to 40 gpm planetary drive system. With no roller chain to worry about, the planetary drive unit delivers hydraulic power directly to the sprocket of the digging chain for optimal trenching performance.The TN760 Trencher can be mounted to a skidsteers between 4000 and 11,000 lbs. |

|

All Baumalight products are sold through our network of equipment dealers. For you, this means better product support, after-sales service, maintenance and product warranty from your local, trusted dealership |

|

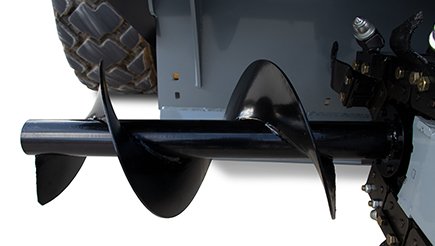

Baumalight Trenchers are designed with a convenient side auger. The side auger keeps the dirt clear from the trenching action but still near the trench when it’s time for back filling.

|

|

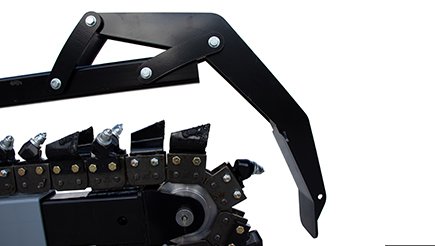

The Trencher has a crumb scraper bar as standard equipment, this helps to scrape and sweep extra dirt and debris into the chain where it is lifted out of the trench. The heavy construction and hinged design mean that the scraper performs no matter what depth of trench you are digging.

|

|

The sealed drive keeps the dirt out and the trencher going. The compact and stron g planetary drive unit delivers the hydraulic power directly to the sprocket of the digging chain for good digging performance. There are no roller chains that jump or stretch. Maximum torque transfer. The motor is mounted directly in-line with the main sprocket. |

|

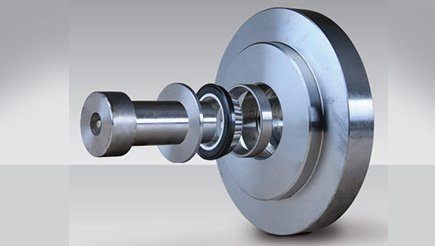

The Baumalight Trencher’s heavy duty nose is precision machined from a piece of solid steel. It runs freely on dual tapered roller bearings to deal with the extreme forces of trenching. Dirt is the enemy of all bearings. A precision machined washer protects the bearings from rocks and dirt. This initial barricade is reinforced by the rubber seal on the bearings, finishing the job is the easily accessible grease fitting which keeps the bearings lubricated and protected from moisture and keeps our nose running freely. |

|

Adjusting the chain tension with a couple of pumps. The grease cylinder tensioner allows you to adjust the tension of the chain quickly with only a grease gun. By applying grease to an internal cylinder the roller nose is pushed forward taking the slack out of the chain. What could be a long frustrating process is now a few quick pumps. |